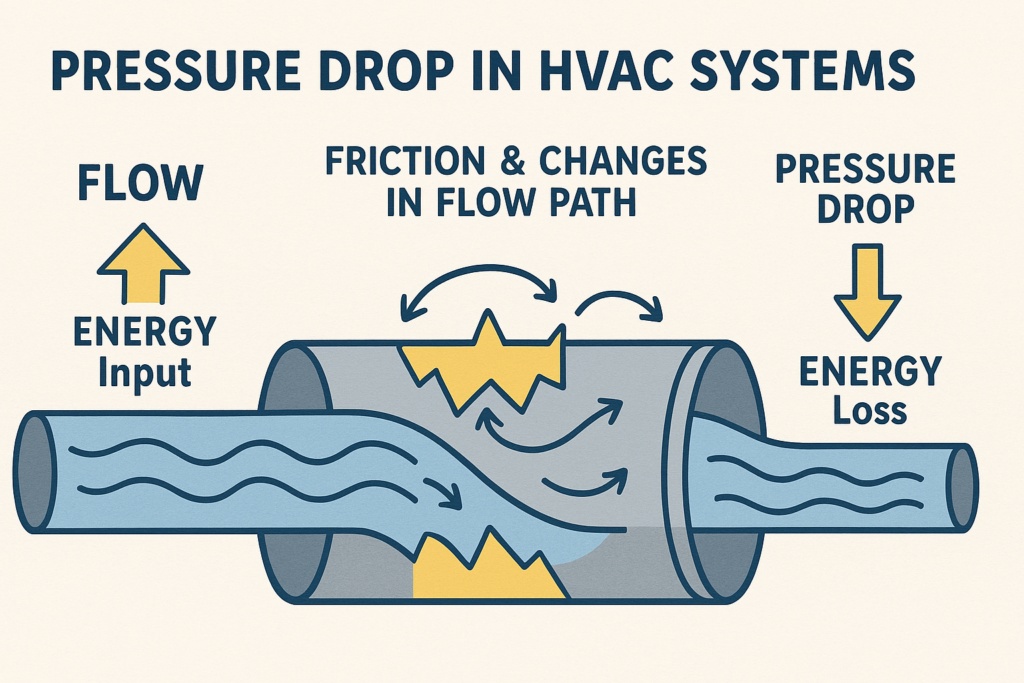

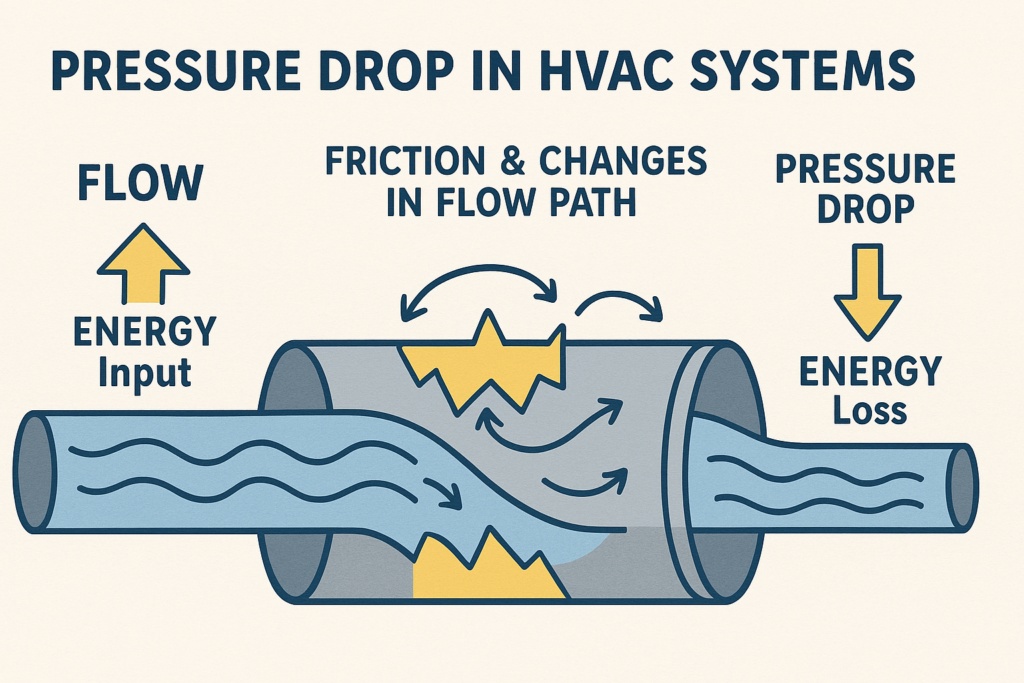

Pressure drop in HVAC systems happens due to friction and flow changes, causing energy loss. Learn how it impacts performance and how to manage it efficiently.

Pressure drop in HVAC systems happens due to friction and flow changes, causing energy loss. Learn how it impacts performance and how to manage it efficiently.