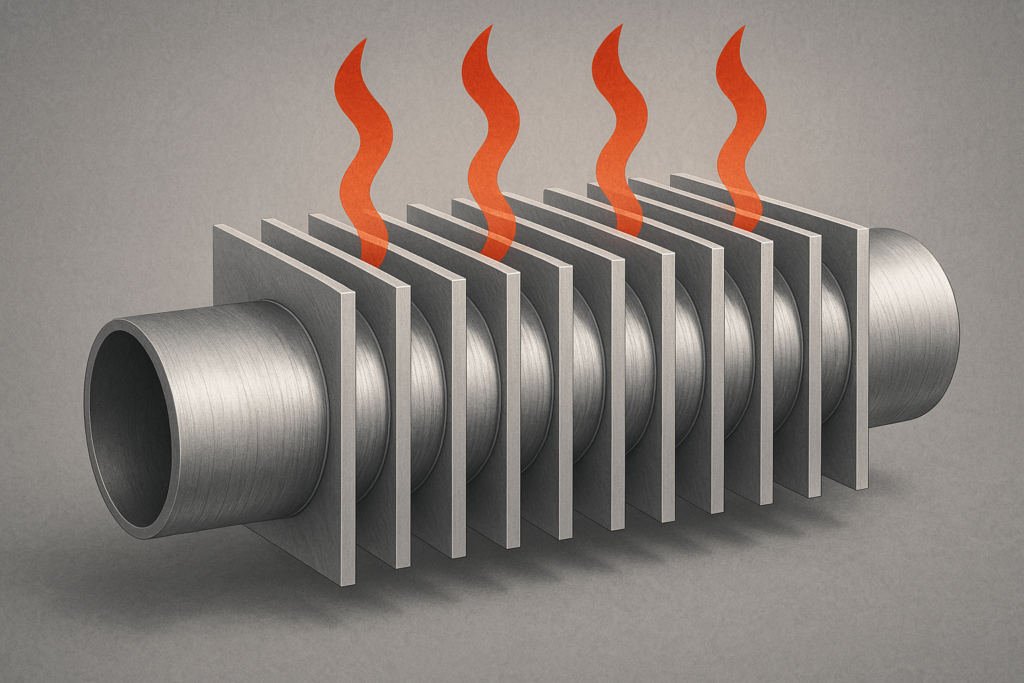

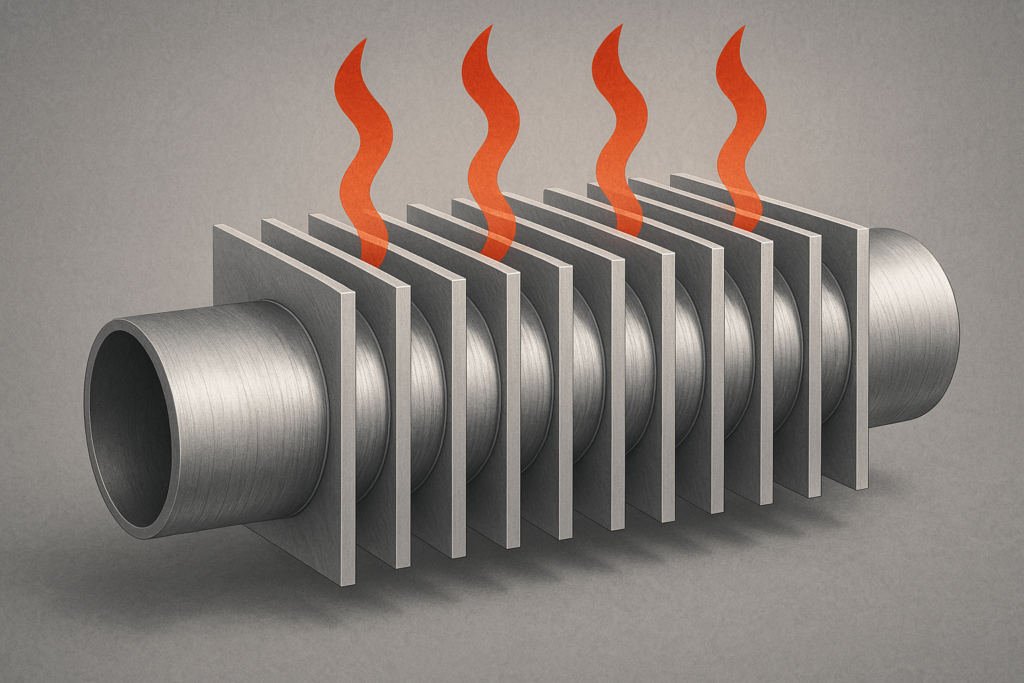

Fin Efficiency Explained — Discover how extended surfaces improve heat transfer efficiency in HVAC systems using simple formulas and real-life examples.

Fin Efficiency Explained — Discover how extended surfaces improve heat transfer efficiency in HVAC systems using simple formulas and real-life examples.