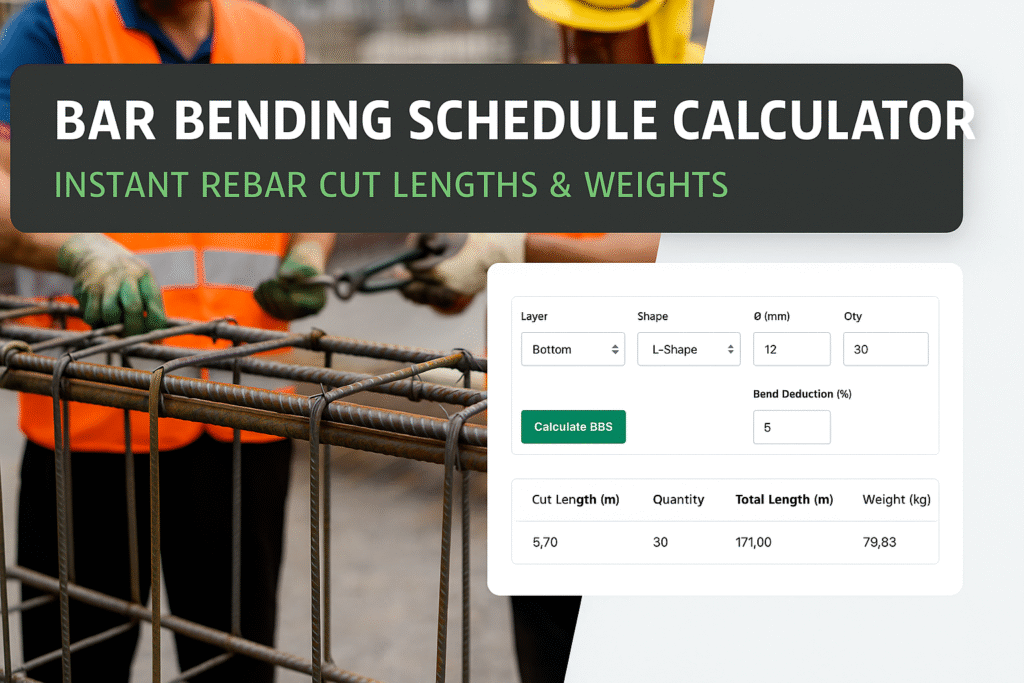

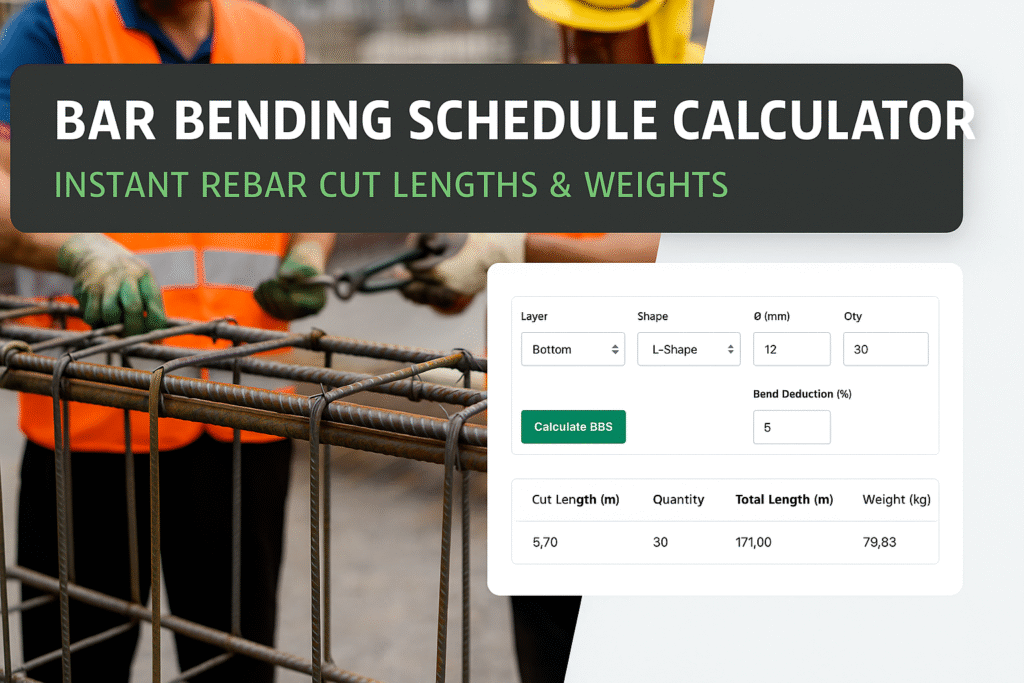

Use this free BBS calculator to compute steel bar weight and cut lengths. Supports top/bottom layers, bends, and professional report generation.

Use this free BBS calculator to compute steel bar weight and cut lengths. Supports top/bottom layers, bends, and professional report generation.