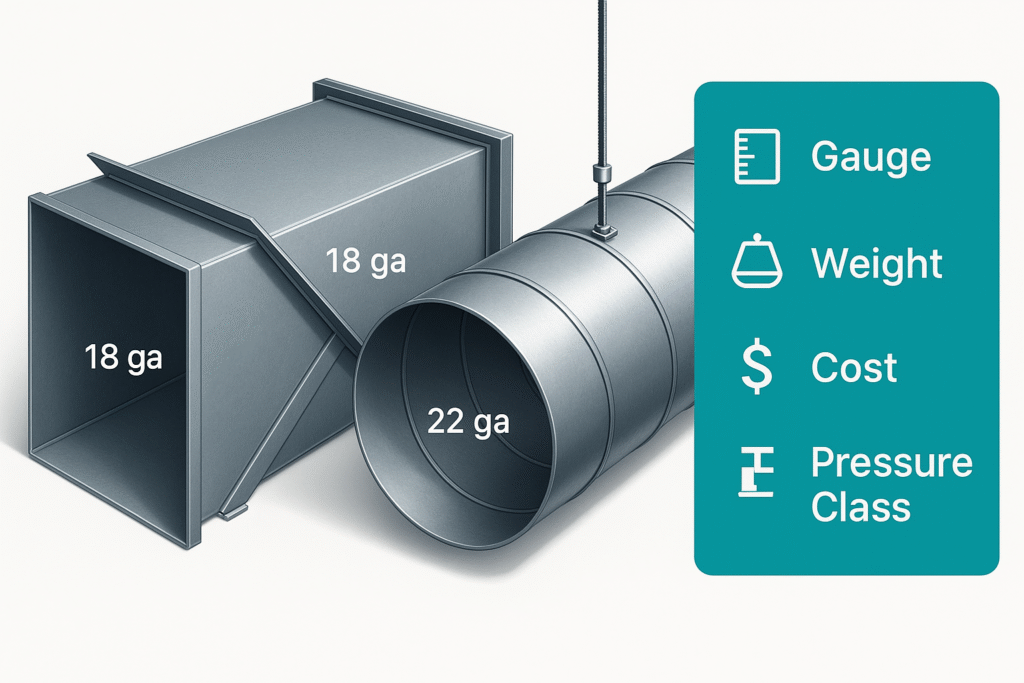

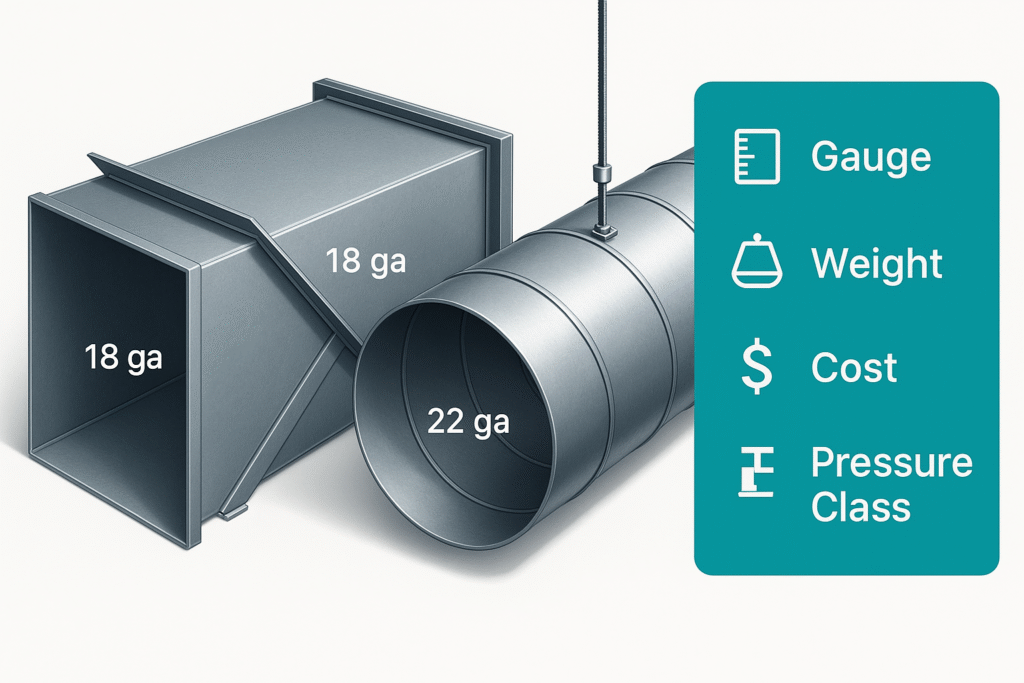

Gage Tables Estimator helps HVAC pros auto-select duct gauge, thickness, reinforcement, and hanger spacing per SMACNA standards with cost & weight.

Gage Tables Estimator helps HVAC pros auto-select duct gauge, thickness, reinforcement, and hanger spacing per SMACNA standards with cost & weight.