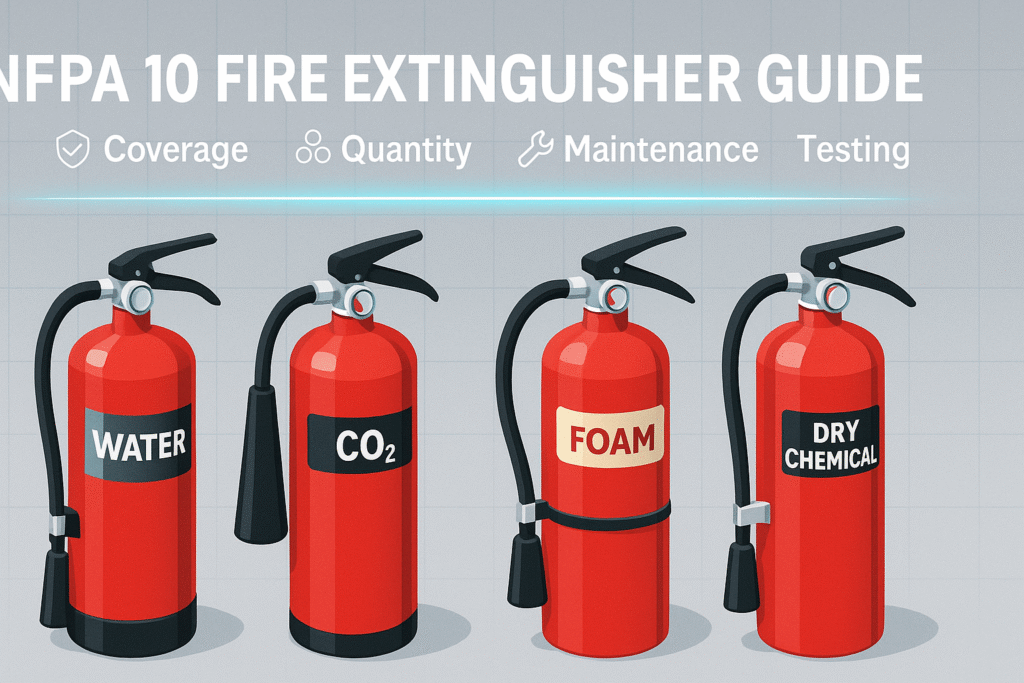

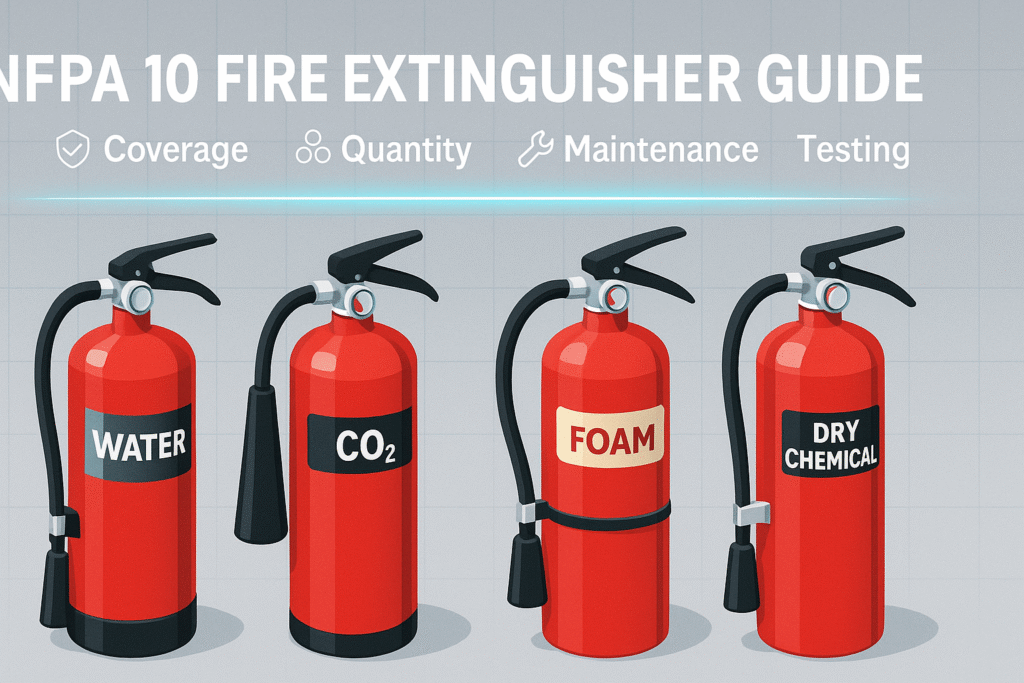

NFPA 10 Fire Extinguisher Guide with coverage per unit, quantity, maintenance intervals, hydro testing, and full inspection checklist in plain English.

NFPA 10 Fire Extinguisher Guide with coverage per unit, quantity, maintenance intervals, hydro testing, and full inspection checklist in plain English.