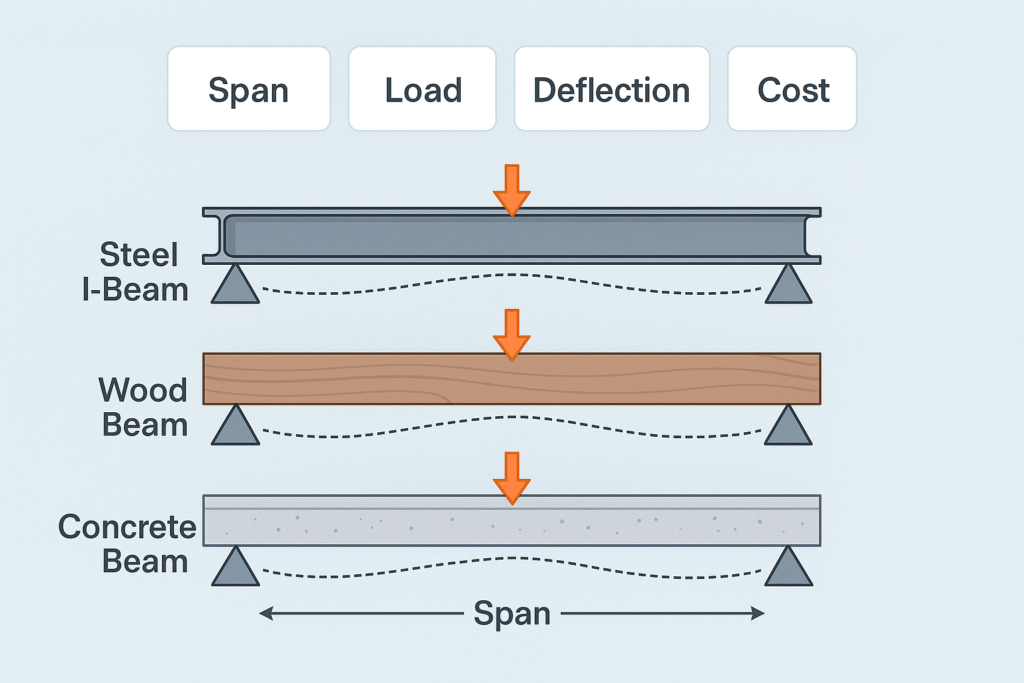

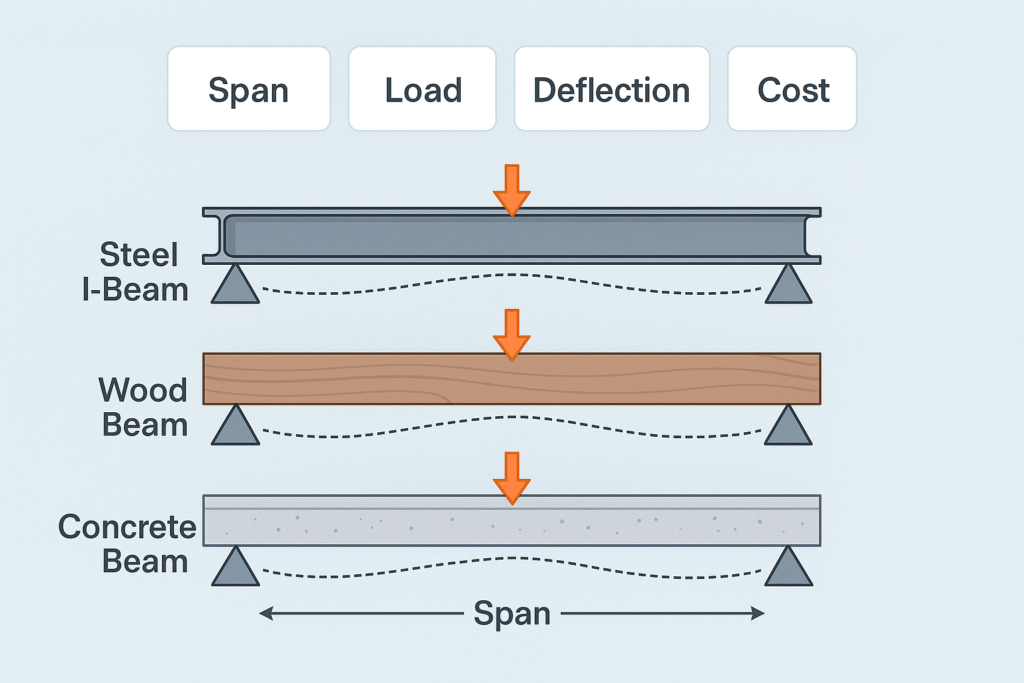

Beam Load Calculator that sizes steel, wood & concrete beams, checks deflection, and estimates cost for India, US & UK – all in one interactive tool.

Beam Load Calculator that sizes steel, wood & concrete beams, checks deflection, and estimates cost for India, US & UK – all in one interactive tool.