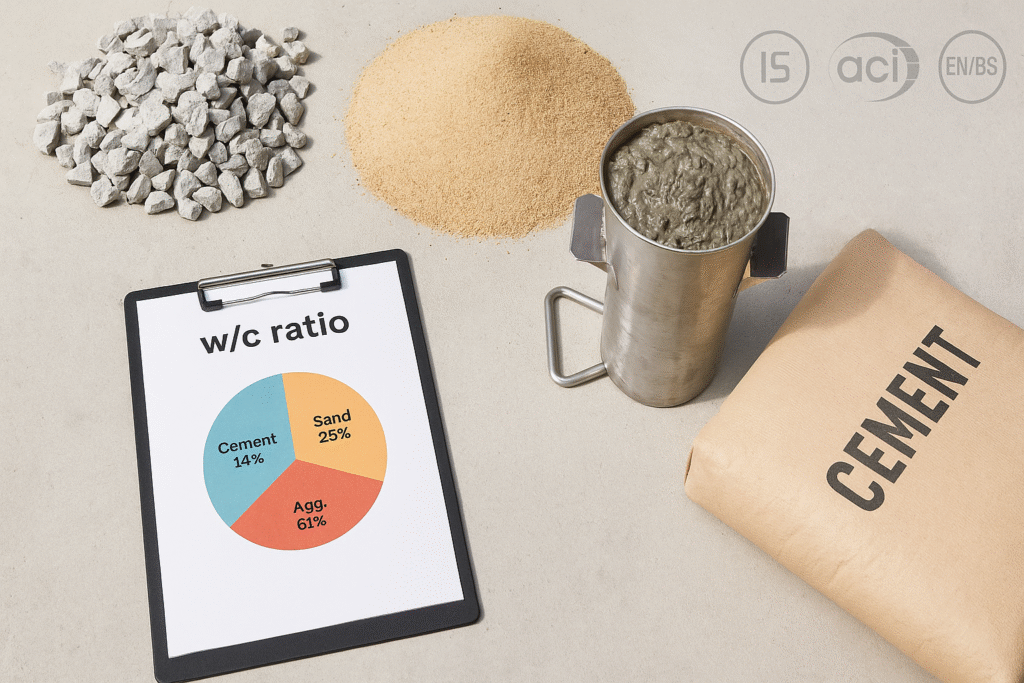

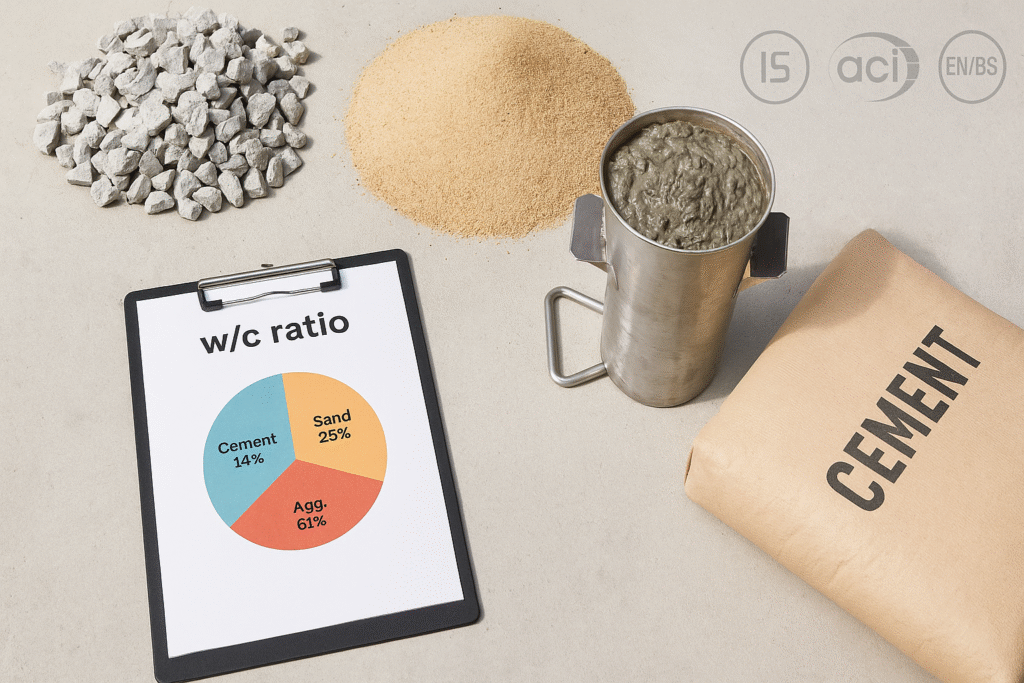

Concrete Mix Design Calculator for IS, ACI, and EN/BS. Understand purpose, math, presets, and step-by-step usage with examples for student-friendly learning.

Concrete Mix Design Calculator for IS, ACI, and EN/BS. Understand purpose, math, presets, and step-by-step usage with examples for student-friendly learning.