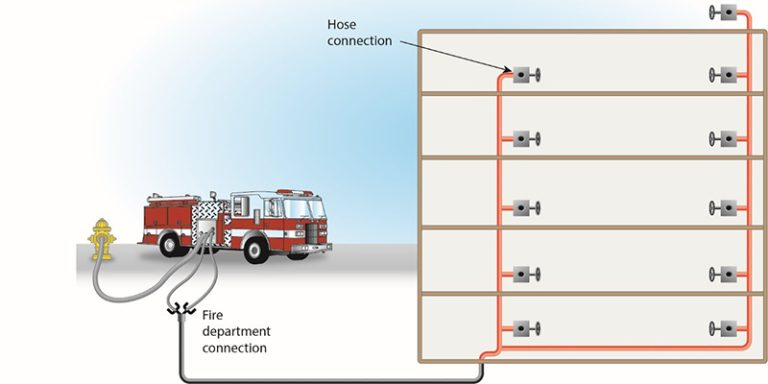

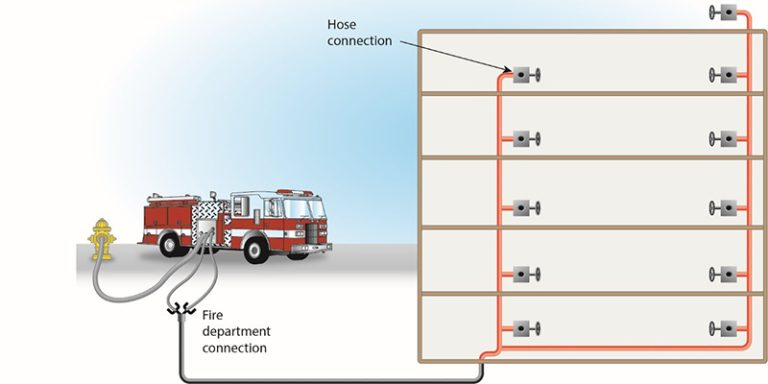

Standpipe system guide for engineers: Learn classes, flow rates, pressure rules & pipe sizing with friction loss calculator based on NFPA 14.

Standpipe system guide for engineers: Learn classes, flow rates, pressure rules & pipe sizing with friction loss calculator based on NFPA 14.