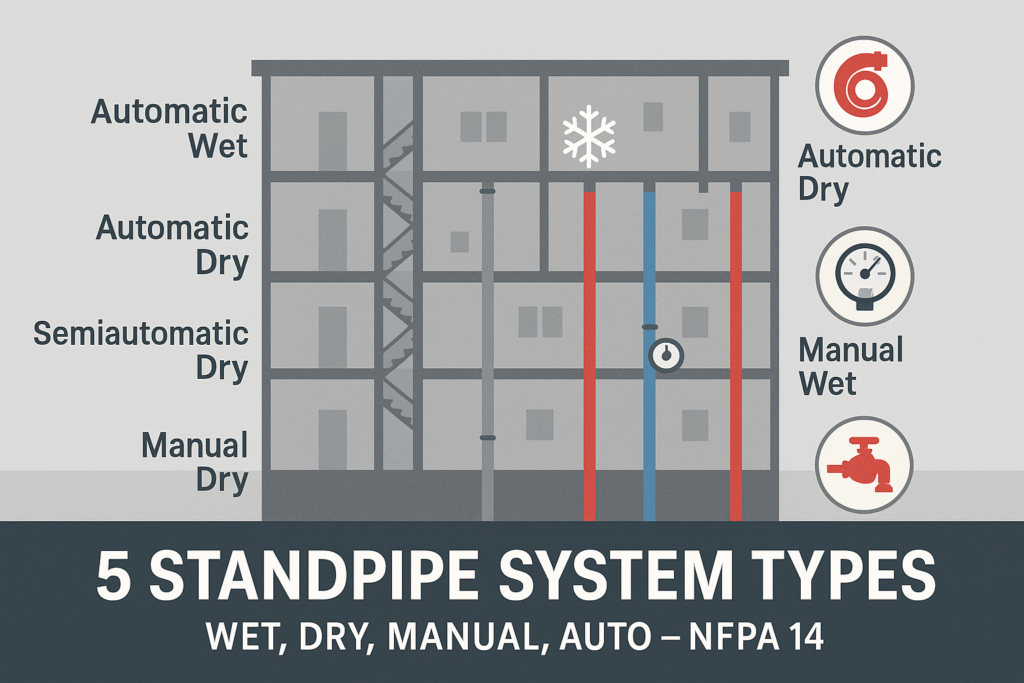

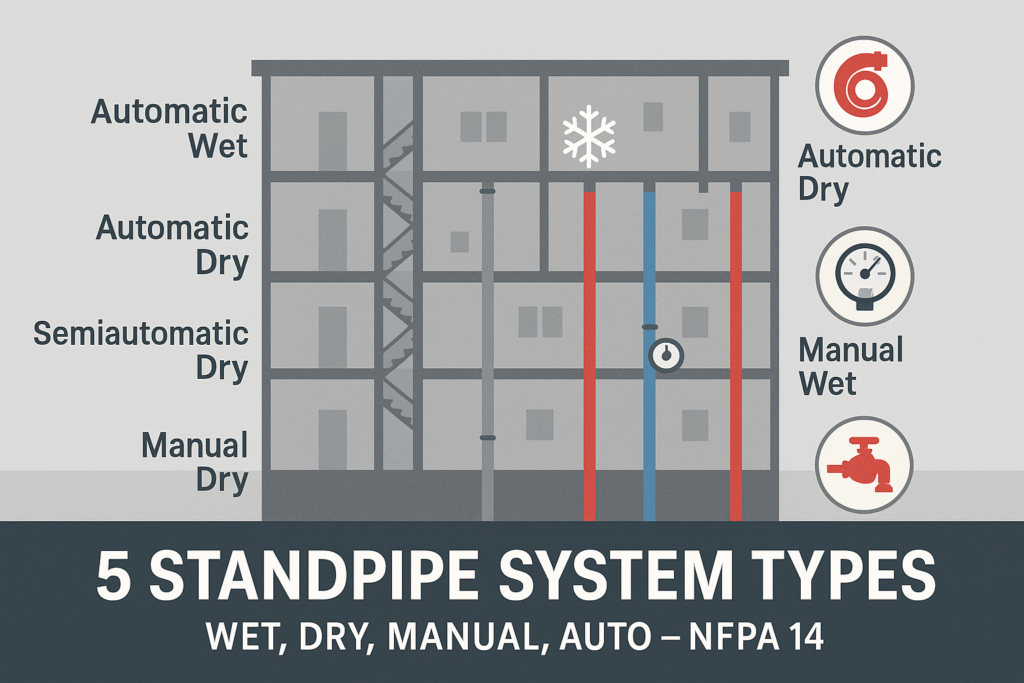

Standpipe System Types like Wet, Dry & Manual systems decoded! Learn where and when to use them as per NFPA 14 with flow rules, tips & easy breakdowns.

Standpipe System Types like Wet, Dry & Manual systems decoded! Learn where and when to use them as per NFPA 14 with flow rules, tips & easy breakdowns.