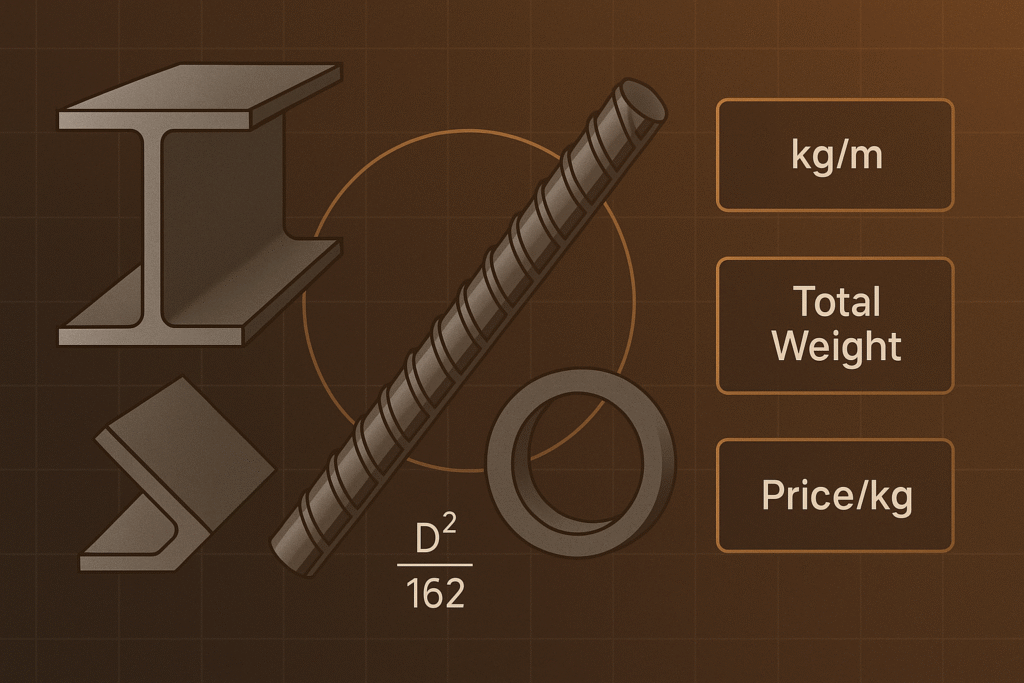

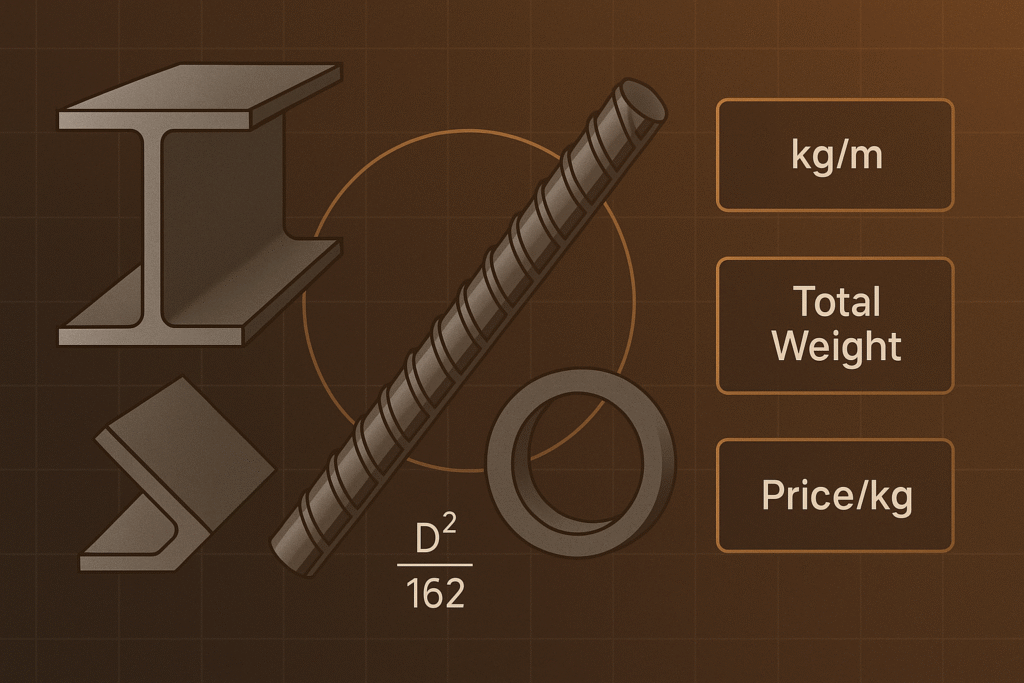

Steel Weight Calculator for bars & 8+ sections—live kg/m, total weight, and 2025 price-based costs with animated previews and a downloadable HTML report.

Steel Weight Calculator for bars & 8+ sections—live kg/m, total weight, and 2025 price-based costs with animated previews and a downloadable HTML report.