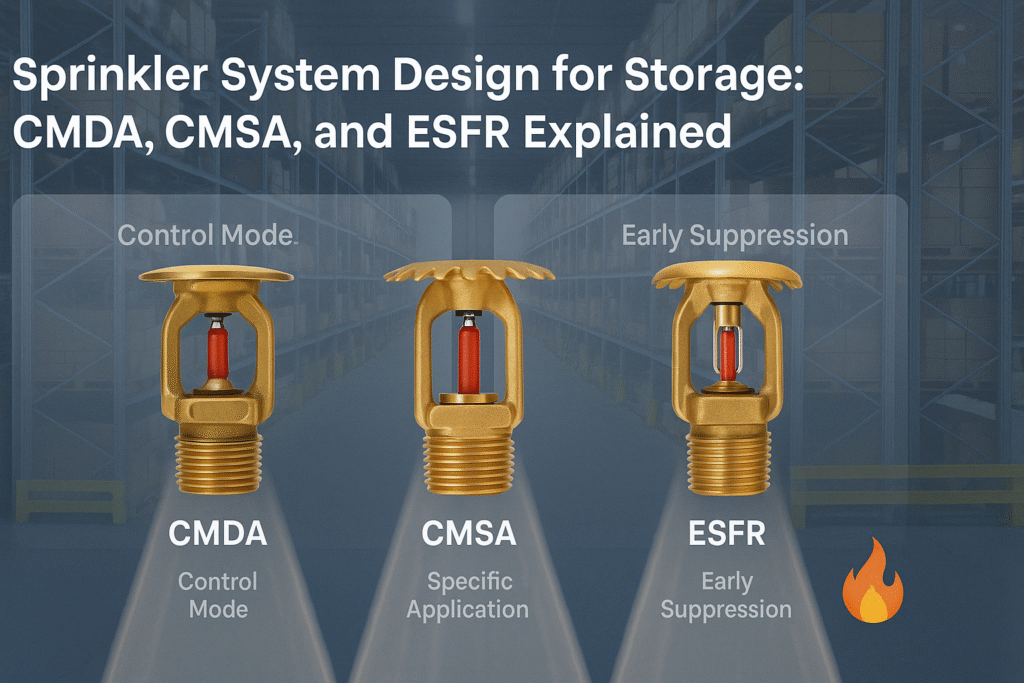

Learn Storage Protection under NFPA 13! Understand Class I-IV commodities, plastics, and sprinkler design. Easy guide for beginners! 📦🚿

Learn Storage Protection under NFPA 13! Understand Class I-IV commodities, plastics, and sprinkler design. Easy guide for beginners! 📦🚿